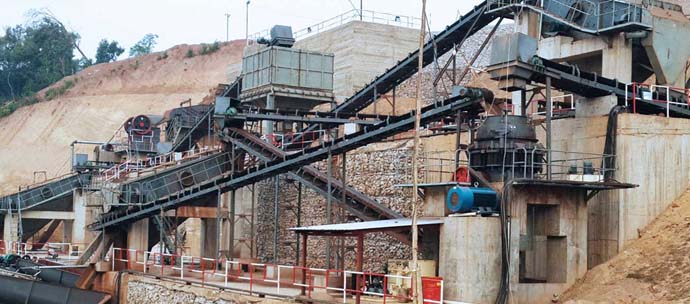

Quarry Crusher

Quarry crusher with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sand stone making, etc. The machinery's pressure resistance strength is under 350Mpa. And stone quarry crusher from turkey are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc.

The quarry crusher is a real rock composition with a range of storage devices used for the decomposition and reduction of content. This is really a function of the hybrid composite bond, which is usually based on the rock front. Generally include primary crusher and crushing machines jaw and gyratory crusher, impact crusher, or a lonely steel mills to reduce the size of the rock. Breaking stones to compact and more can use double or three roll crusher, cone crusher, or simply the size of hammer crusher.

Processing of quarry crusher

Quarry stone production line is the production of construction equipment. It mainly includes: jaw crusher, impact crusher, hammer type crushing square box, vibrating feeder, vibrating screen, sand washing machine, belt conveyor. Stone production line of 50%, energy saving, compared with the traditional sand making machine. It can put all rock, gravel, made of various sizes of stones and sand together to building sand, sand grain size uniformity, high strength, than natural sand, ordinary hammer hit HeLuanShi pressure blasting machine production conforms to the architectural requirements can increase the construction quality. The quality and performance of the production line equipment, reliable, reasonable design, convenient operation, work efficiency is higher

Features of quarry crusher

- Higher capacity and less wear costs;

- Wide range of application suitability;

- Easy to maintain, reduce the downtime and maintenance costs;

- Stable running performance and easy operation;

- Stable bevel wheel transmission device;

- Balanced runout rotation ensures best capacity;

- Proper operation, continuously load until the machine shut down scheduled.

Technical Data

| Model | Cavity | Recommended Minimum Discharge Setting A (mm) | Feed Opening With Min.Recommended Discharge Setting A (mm) | Capacities In Tons Per Hour Passing Through The Crusher At Indicated Discharge | Power(KW) | |

|---|---|---|---|---|---|---|

| Opening Side"B" | Closed Side"B" | |||||

| 36"(3') | Fine | 9 | 102 | 83 | 45-93 | 75 |

| Coarse | 13 | 175 | 159 | 59-165 | ||

| Extra Coarse | 25 | 178 | 163 | 129-198 | ||

| 51" (4.25') | Fine | 13 | 137 | 109 | 106-183 | 185 |

| Medium | 16 | 210 | 188 | 132-304 | ||

| Coarse | 19 | 241 | 216 | 171-349 | ||

| Extra Coarse | 25 | 259 | 238 | 230-450 | ||

| 66" ( 5.5' ) | Fine | 15 | 209 | 188 | 180-324 | 240 |

| Medium | 22 | 241 | 213 | 252-437 | ||

| Coarse | 25 | 269 | 241 | 299-634 | ||

| Extra Coarse | 38 | 368 | 331 | 431-680 | ||

| 84" ( 7' ) | Fine | 19 | 278 | 253 | 381-1028 | 400 |

| Medium | 25 | 334 | 303 | 605-1284 | ||

| Coarse | 31 | 369 | 334 | 786-1450 | ||

| Extra Coarse | 38 | 460 | 425 | 886-1637 | ||