Sand Making Machine

Sand making machine is a kind of rock quarry crusher. In the actual production application, the sand making machine fitting because of the long time with the high hardness material grinding. This is very easy to wear and tear caused by sand making machine parts. Therefore, in the production of sand making machine, we should pay attention to the timely replacement of sand making machine parts, can be in the part of the equipment to ensure that the overall effect of the equipment is better. Therefore, in the purchase of sand machine accessories should also pay more attention, only to choose the product price.In the purchase process, must first determine the size of the sand stone, if the conditions are broken, crushed sand machine, can be used directly. If the material contains different ratios of sand size, can be screened, and then according to the requirements of different materials to select the appropriate crushing equipment.

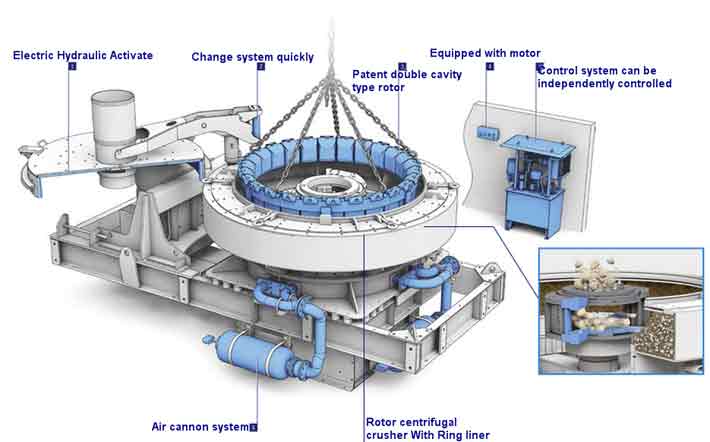

Structure Of Sand Making Machine

Sand making machine is mainly composed of seven parts, such as feeding hopper, distributor, vortex chamber, impeller, shaft, base drive device and motor. Hopper at the entrance to the bucket shape, mainly for filling material and then drop to the bottom of the hopper dispenser, mainly for the percentage points. The vortex crushing cavity can also bearing materials, the formation of the lining material, the broken material occurs in the vortex crushing cavity, including lining material will be separated vortex crushing chamber wall, crushing crushing effect between effect is limited material, has the effect of wear due to the crushing cavity, spindle assembly, motor, transmission device is installed plays a supporting role in the bottom of the sit.The base.

Features Of Sand Making Machine

- The deep cavity type rotor is optimized by 30% to improve the material straight through volume.

- Modular design hammer, only need to replace the wear parts wear out, it can reduce the cost of more than 30%.

- Core wear-resistant material is highly resistant to abrasion and high temperature resistant material.

- The diamond impact block is avoided and the support plate is damaged.

- International brands of bearings used in Sweden and the United states.

- The best shooting mouth and multiple fluid curve design reduce the resistance to material flow, and improve the material

- straight through capacity.

- Special seal structure, in the main shaft end, to ensure that no leakage, even without oil seal.

- Hydraulic opening device adopts Japanese imported fittings, it is easy and quick to move on the cover, so that the internal mechanical maintenance and replacement costs lower labor efforts.

Technical Data

| Model | Feed at center&sides | Feed at center | Soft Material | Hard Material | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

|---|---|---|---|---|---|---|---|---|

| Capacity (t/h) | Max.Feeding (mm) | |||||||

| B-7611 | 120-180 | 60-90 | 35 | 30 | 1700-1890 | 4-55×2 | Y250M- 4/55 | 4100×2250×2258 |

| B-8518 | 200-260 | 100-130 | 40 | 35 | 1520-1690 | 4-90×2 | Y280M- 4/90 | 4140×2280×2425 |

| B-9526 | 300-380 | 150-190 | 45 | 40 | 1360-1510 | 4-132×2 | Y315M-4/132 | 4560×2450×2780 |

| B-1140 | 450-520 | 225-260 | 50 | 45 | 1180-1310 | 4-200×2 | Y315L2-4/200 | 5100×2690×3200 |